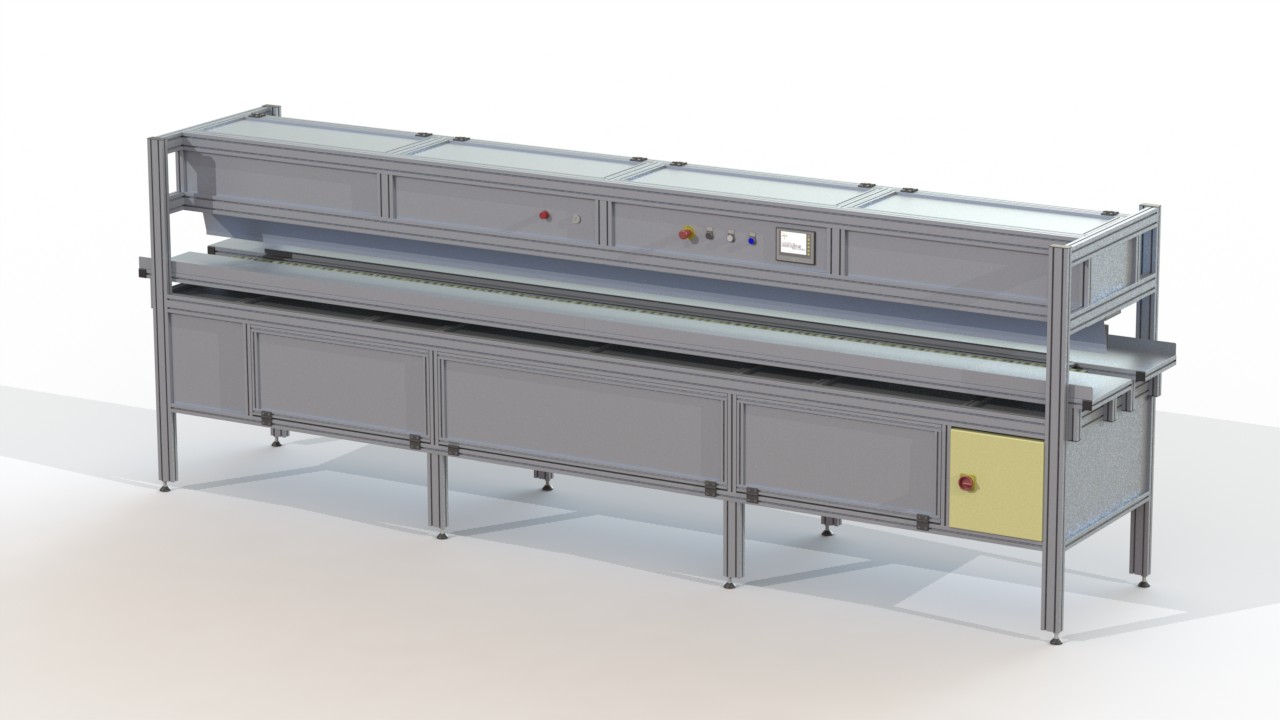

SB6000

Semi-automatic station for 6 m double-sided adhesive application

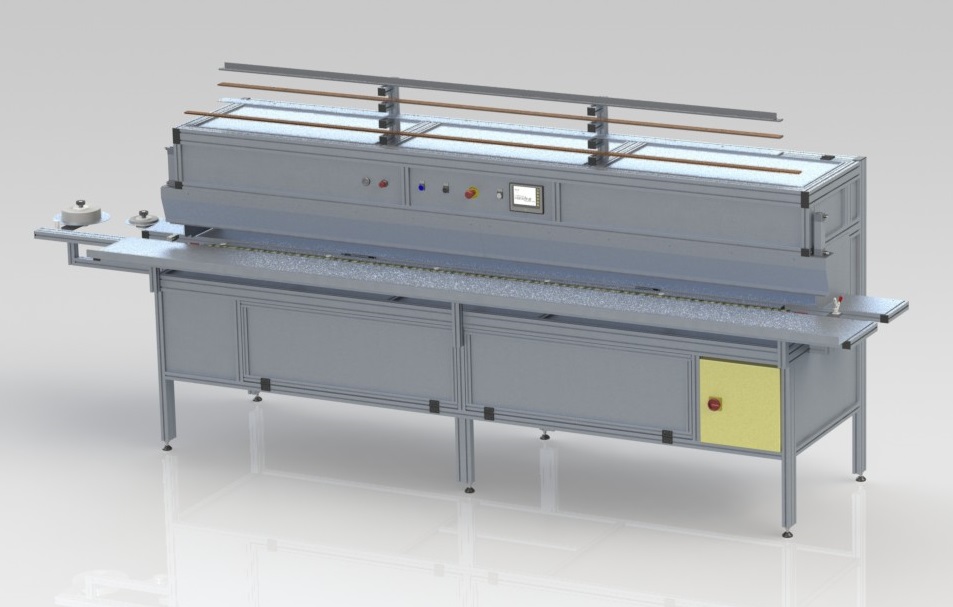

Semi-automatic equipment for applying double-sided adhesive tape on a tube and inserting an anti-wind brush (on 2 lateral guides at the same time) for the production of mosquito nets. Maximum measure 6 meters.

The machine can be used by a single operator while still guaranteeing a high number of cycles.

When working with tubes for mosquito nets it is possible to decide whether to remove the paper support of the double-sided tape or leave it in order to then be able to store the tube complete with the tape.

Through the touch-screen of the control panel, in addition to entering all the settings necessary for processing, it is possible to set the machinery for processing by means of a set measurement or automatically with reading of the length of the material with a magnetic sensor.

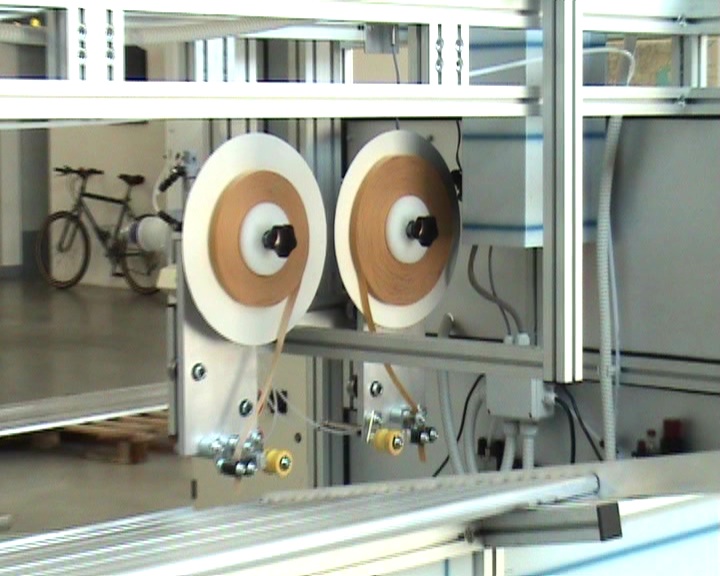

During the production phase, it is possible to adapt the trolleys for the application of the double-sided tape on pipes of different diameters and on lateral guides of different heights.

The display allows you to view different programs for toothbrush and double-sided adhesive so as not to make mistakes in use.

The trolleys in hardened steel guarantee maximum speed and precision to optimize the processing time to the maximum.

If possible it is possible to adapt multiple slots of profiles to which to apply tape or brush. Our staff is available to manage the necessary changes and possibly discuss other changes.

Technical information

Maximum length – mm 7270

Maximum depth – mm 700

Max height – mm 1360

Mains voltage – V 220

Absorbed power – Kw 1

Operating pressure – Bar 6

Weight – kg 300

For information on prices and delivery times, you can contact us by phone or email with your requests.